Rockassist

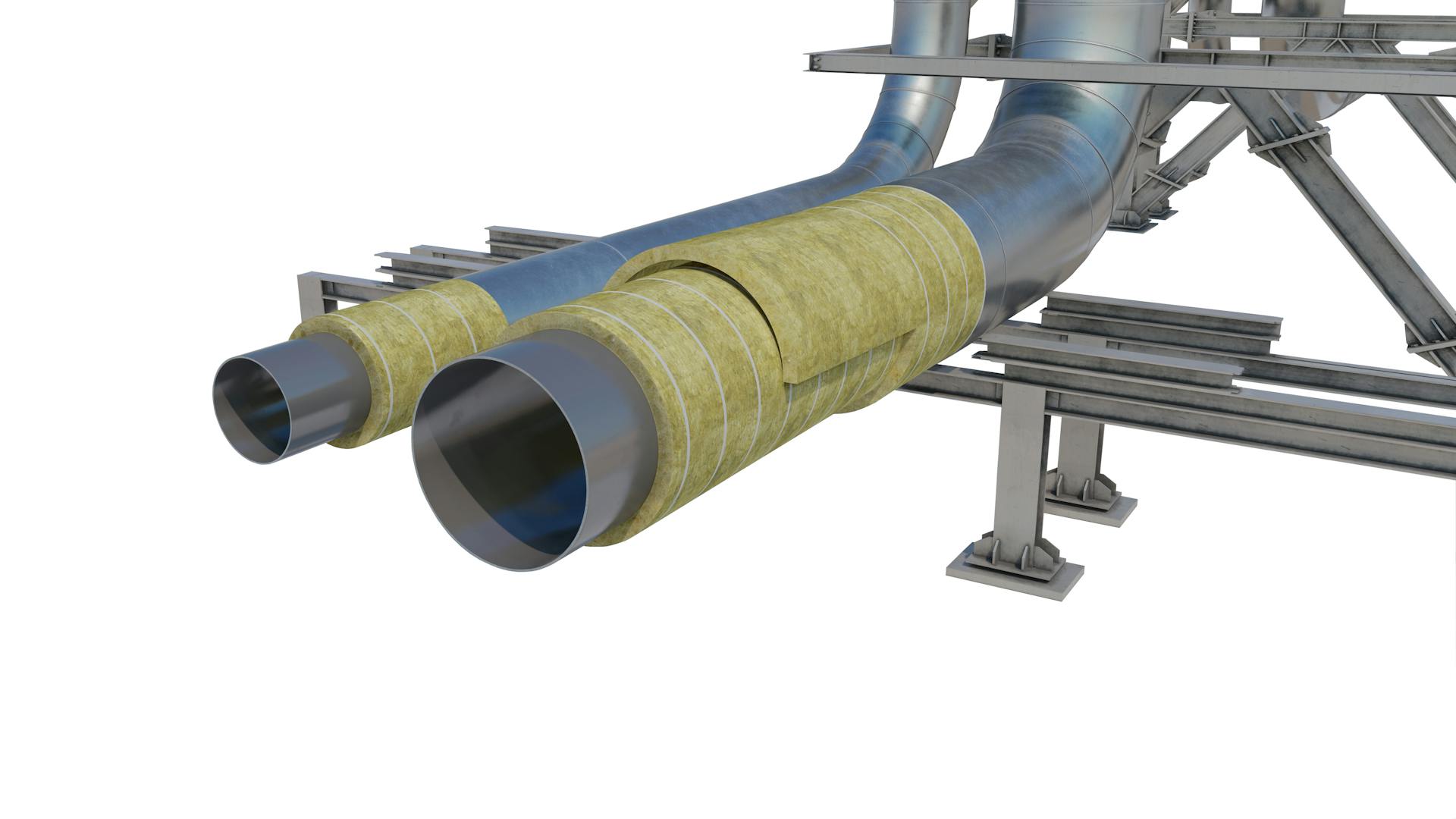

Rockassist is a unique state of the art calculation tool for thermal calculations of technical installations in the process industry, marine & offshore.

Rockprice

Rockprice is our efficient online price tool to view, in real time, the actual prices of our ROCKWOOL ProRox and SeaRox product range/assortment.